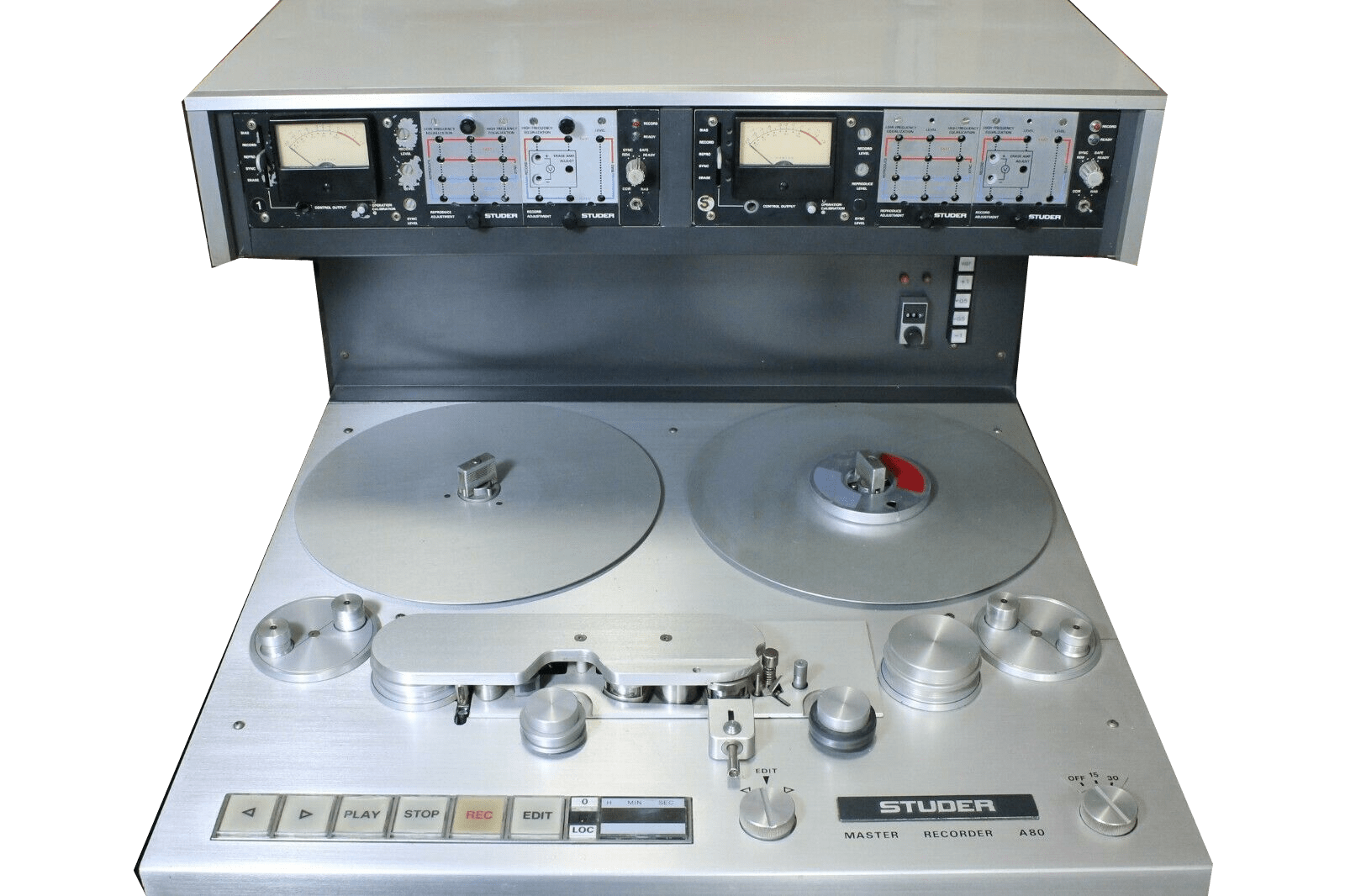

Technical Details

Brand: Studer

Model:A-80

Category:Super High Fidelity

Application:Studio

Electronics:Solid State

Equalization:IEC

Country of Manufacture:Switzerland

Tracks:1/2 Rec/PB

Speeds: 7 1/2

Max Reel Size("): 10.5+"

Number of heads: 3

Head Composition: Permalloy

Head Configuration: Stereo - Stacked

# Motors: 3

Auto Reverse?:No

Voltage(s): 110-120v, 220-240v

Outputs: XLR Balanced

Frequency Response:30Hz-18Khz @15 ips 30Hz-15Khz @7.5 ips

Wow and Flutter:.04% @ 15ips .06 at 71/2ips

Signal-to-Noise Ratio:61 Db at 15ips 58 Db at 71/2ips

Sound quality rating:9 / 10

Long-term reliability rating: 9/ 10

Additional Details

Description

The Studer A-80 studio recorder is a versatile machine with more options than most, that many feel, is the best tape machine ever designed. You can run tape widths starting at 1/4 inch all the way up to 2 inch with a change of headblock, reel adapter, tape guides and capstan motor shaft.

You can configure this tape recorder from one channel (mono) up to 24 channels depending on your requirement.

Various Models/Options

7.5/15 or 15/30 IPS Available for both models

The R comes without VU meters

RC versions have VU meter options. The RC version is more recent

RC MK1, MK2 & MK4 versions as well

R/RC versions are only

An A80 RC VU MK2 should sell for more than a A80 R

Opinions

The earliest, quarter-inch A80 R had the best headblock design. That excellent original design was soon compromised when Studers commercial customers demanded changes based on their recording production requirements.

The high-precision radial ball-bearings require replacement in any A80 after every 10 years as the lubricants inside them have deteriorated with age. Many sellers offer what they claim to be replacement Studer bearings, when they are not. One hint is seeing the specification of ABEC classification grade, a US based system that Studer never used.

Of equal importance, is the exact lubricant specification (grease type) and its fill quantity, which varied greatly in the same machine depending on the specific bearing.

After bearing replacement all tape path heights should be adjusted to a tolerance of about one-one-hundredth of a millimeter (0.0004 inch), using Studer factory gauging.

Finally, the critical and exacting matter of adjusting the axial pre-load force after a new bearing has been installed. (Don’t understand why measuring and adjusting axial pre-load force is critical in a precision guidance tape transport? You’re not alone. The vast majority of even highly experienced tape recorder technicians that have attended service training programs at ATAE, have not been able to correctly explain what axial pre-load is on their course entry exams.)

From the service manual

Capstan servo

The tape drive has a sturdy asynchronous high torque motor which is operated far below its maximum speed. The speed is scanned inductively, measured electronically and controlled automatically.

For measuring the actual speed, 120 grooves are cut very accurately into the outside of the motors armature to compensate for any remaining matching tolerances, the grooves are scanned by two magnetic heads set at 180° to each other the signal so derived is amplified, limited and shaped by transistors Q1 through Q4 and transmitted to a discriminator (highly constant LC series circuit) either directly or for higher speeds divided by the ratio of 1:2

It is possible to vary the motor speed by plus or -3% from the outside by means of a DC correcting signal. The stability of this drive is such that the Studer A-80 can be operated without modification on either 50 Hz or 60 Hz voltage supplies. The plug-in amplifier Boards for the A-80 had electronics for record, line amplifier, sync and meter amplifier.

Control electronics

In the interests of optimum accessibility for servicing, the whole of the tape deck control is concentrated on PC boards of identical size in a control unit-rack assembly. The rack contains the following PC boards

oscillator 1.080.399

attenuator 1.080.396

IC memory & counter 1.080.393

IC decoder and drivers 1.080.390 &.391

capstan servo 1.080.372/375

spooling motor control 1.080.383, 1.080.384

spooling motor contactors 1.080.380, 1.080.381 (these two boards are fully interchangeable)

voltage stabilizer 1.080.370

Control logic

attenuator and preamp 1.080.396.00

IC memory and counter 1.080.393.00

IC decoder and drivers 1.080.390.00, 1.080.391.00

Repro Head (1.317.135)

Record Head (1.317.130)

Many of the Studer and Revox machines used Frako and Rifa capacitors which are recommended to be replaced.

Links

A short and concise Timeline /History on the A-80

New old stock replacement parts

Artists with A-80’s

Tom Waits Used an A-80 24-track machine, with Dolby SR to record Bone Machine, as stated by engineer Biff Dawes in a Mix Online interview February 26, 2015.

The same A80 was used to record Mule Variations, reported in issue 9 of Audio Technology Magazine.

As a result of using these various room mics, King sometimes ended up with a full 24-track, which meant that choices had to be made upon which room mics to use. The 24-track that was used was a late ‘70s Studer A80 MkIII, with BASF 900 tape, no Dolby, 30ips, recorded at +6, “hit very hard, which gives more tape compression”. The album was mixed to analogue, an Ampex ATR102, on a half-inch tape running at 30ips, without Dolby.

Kate Bush’s studio featured two A 80 1/2″ Recorders, used to record The Hounds of Love, The Sensual World & The Red Shoes.

Additional Info

Specs

Frequency Response 30Hz-18Khz @15 ips 30Hz-15Khz @7.5 ips

Wow and Flutter .04% at 15 .06 at 7 1/2

Signal-to-Noise Ratio 61 Db at 15 58 Db at 7 1/2

Equalization: CCIR

Canon XLR connectors for audio connections

Reel size: up to 12,5″ (31,8 cm) for metal reels or plates.

Balanced XLR input and output.

Digital timer display; H, Min, Sec.

Edit mode with Jog and Shuttle function.

Butterfly heads.

Weight: 50 Kg+

Dimensions: H x W x D, 900 x 700 x 600 mm

100v-240v internally adjustable